#GraphicOnlineGhanaMonth: Do you know about the popular 'Kantamanto Dry Gin'

As part of the Graphic Ghana Month reflections, the Kantamanto Dry Gin and all you need to know about it, how it was distilled and how it became very popular in the 1960s and beyond is on the feature today.

Advertisement

If one were asked to give a simple definition of Gin, the answer probably would be that Gin is diluted alcohol flavoured with botanicals.

One of the most important of the botanicals used for flavouring is Juniper; it is from the first syllable of the word Ginevra - Italian for Juniper - that the spirit gets its name.

"LONDON" Gin Is unsweetened gin, not an indication of the place of manufacture. KANTAMANTO Dry Gin was a London type Dry Gin made in GHANA; other "London" type gins were made all over the world.

Rum and Whisky get their flavour from the same source from which the spirit is distilled and their character from the "impurities" which remain after distillation and which mellow during the process of maturation.

With gin on the other hand, the flavour is carefully infused, an ageing period is not necessary and may, in certain circumstances be undesirable. Simple though this definition may be the manufacture of a high class product like "KANTAMANTO" Dry Gin needs complicated and expensive equipment and a skillful application of the distiller’s art.

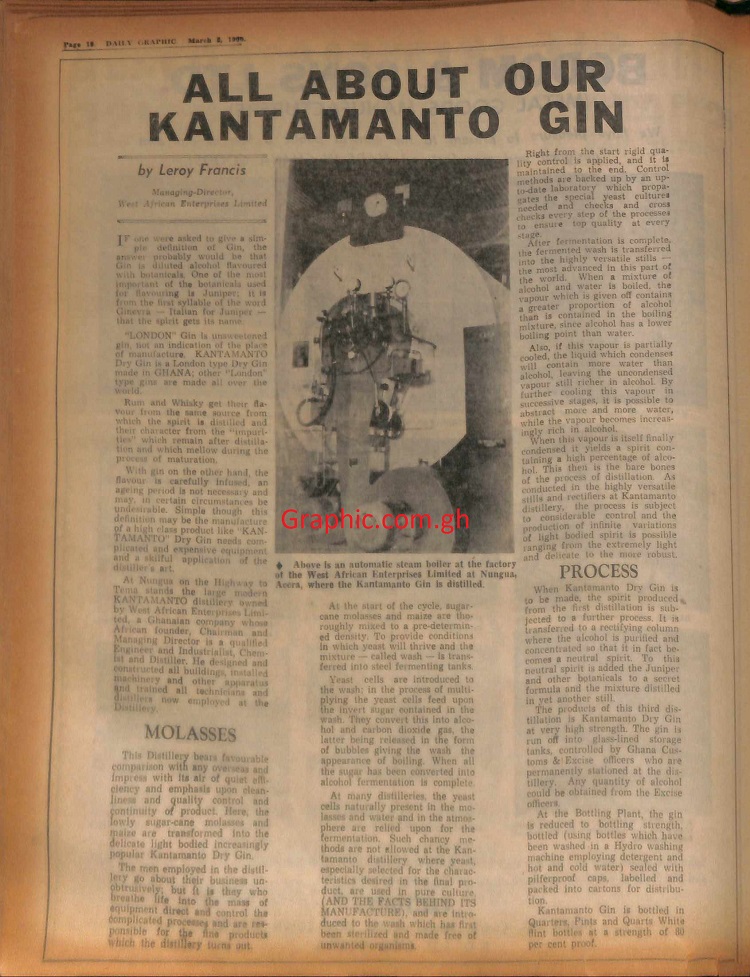

At Nungua on the Highway to Tema stood the large KANTAMANTO distillery, which was owned by West African Enterprises Limited, a then Ghanaian company whose African founder, Chairman and Managing Director was a qualified Engineer and Industrialist, Chemical and Distiller.

He designed and constructed all buildings, installed machinery and other apparatus and trained all technicians and distillers who were employed at the Distillery.

Molasses for Kantamanto Dry Gin

This Distillery bears favourable comparison with any overseas and Impress with its air of quiet efficiency and emphasis upon cleanliness and quality control and continuity of product. Here, the lowly sugar-cane molasses and maize are transformed into the delicate light bodied increasingly popular Kantamanto Dry Gin.

The men employed in the distillery went about their business unobtrusively; but it was they who breathe life into the mass of equipment direct and controlled that complicated processes and were responsible for the fine products which the distillery turned out.

At the start of the cycle, sugarcane molasses and maize were thoroughly mixed to a predetermined density. To provide conditions in which yeast will thrive and the mixture - called wash - is transferred into steel fermenting tanks.

Yeast cells were introduced to the wash; in the process of multiplying the yeast cells feed upon the Invert sugar contained in the wash. They convert this into alcohol and carbon dioxide gas, the latter being released in the form of bubbles giving the wash the appearance of boiling. When all the sugar has been converted into alcohol, fermentation is complete.

At many distilleries, the yeast cells naturally present in the molasses and water and in the atmosphere are relied upon for the fermentation, Such chancy methods were not allowed at the Kantamanto distillery where veast, especially selected for the characteristics desired in the final product, were used in pure culture (AND THE FACTS BEHIND ITS MANUFACTURE), and are Introduced to the wash which has first been sterilized and made free of unwanted organisms,

Right from the start rigid quality control is applied, and it maintained to the end.

Control methods were backed up by an up-to-date laboratory which propagates the special yeast cultures needed and checks and cross checks every step of the processes to ensure top quality at every stage.

After fermentation was complete, the fermented wash was transferred into the highly versatile stills - the most advanced in this part of the world. When a mixture of alcohol and water is boiled, the vapour which is given off contains a greater proportion of alcohol than is contained in the boiling misture, since alcohol has a lower boiling point than water.

Also, if this vapour was partially cooled, the liquid which condenses will contain more water than alcohol, leaving the uncondensed vapour still richer in alcohol. By further cooling this vapour in successive stages, it is possible to abstract more and more water, while the vapour becomes increasingly rich in alcohol.

PROCESS

When Kantamanto Dry Gin was to be made, the spirit produced from the first distillation was subjected to a further process. It was transferred to a rectifying column where the alcohol was purified and concentrated so that it in fact becomes a neutral spirit. To this neutral spirit is added the Juniper and other botanicals to a secret formula and the mixture distilled in yet another still

The products of this third distillation Is Kantamanto Dry Gin at very high strength. The gin is run off into glass-lined storage tanks, controlled by Ghana Customs & Excise officers who were permanently stationed at the distillery. Any quantity of alcohol could be obtained from the Excise officers.

At the Bottling Plant, the gin was reduced to bottling strength, bottled (using bottles which were washed in a Hydro washing machine employing detergent and hot and cold water) sealed with pilferproof caps, labelled and packed into cartons for distribution.

Kantamanto Gin was bottled in Quarters, Pints and Quarts White Mint bottles at a strength of 80 per cent proof.